Automation

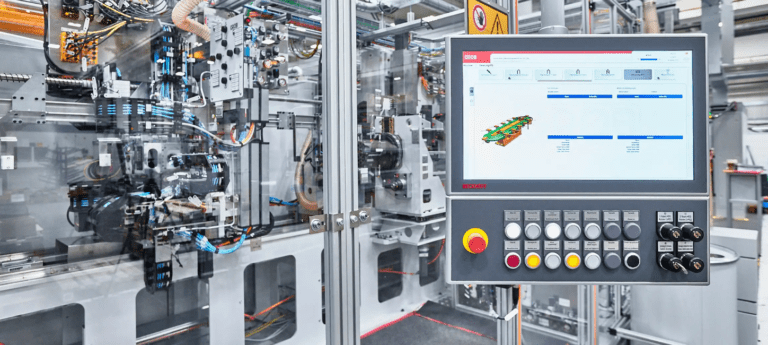

AUTOMATION AND CONTROL SYSTEM

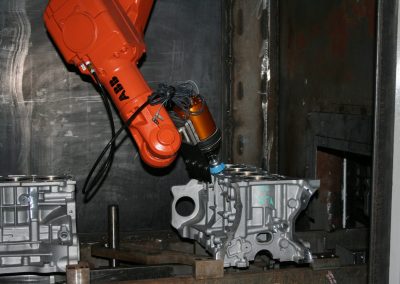

At laing international business solution we create customized process automation according to the needs and objectives of our clients, ranging from basic automation to advanced automation, including distributed control systems, PLC systems, intelligent CCMs with any standard communication protocol, as well as such as energy management and metering. We have a technological development department that can design automated machinery that adapts to the specific needs of our clients.

have experience, highly qualified personnel, specialized equipment and everything necessary to support the industry in general in its modernization and growth projects.

Higher Speed

Greater Precision

Improved Capacity

Design Consistency

Reduced Waste Generation

Granular Control

INDUSTRIAL AUTOMATION AND CONTROL SERVICE