Maintenance

EXTENDED LIFE OF YOUR EQUIPMENT

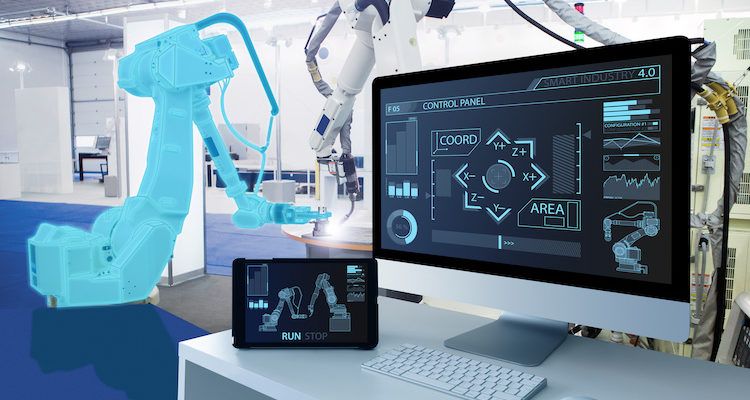

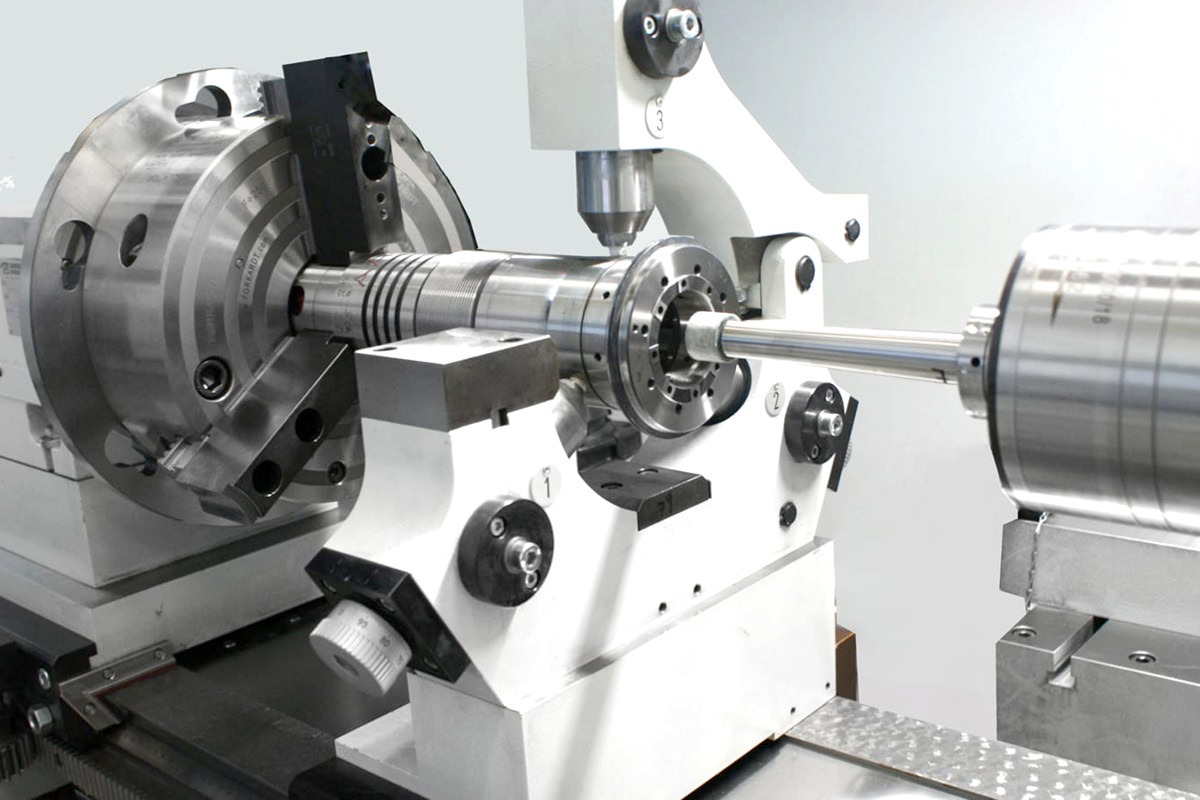

Laing international Business Solutions has an engineering team trained and specialized in the repair of robotic and industrial parts in which they include their restoration of internal and external components in a professional manner, our division of mechanical engineers carry out the convincing tests in which they carry I finished a complete inspection of the components that range from the servomotors, robotic arms and control systems that make it up, including as an important part the maintenance of custom robotic systems (fixtures). All services are performed with the highest standards.

At LAING, we help your bottom-line by extending the life of your equipment. If you have machines that are not performing as it used to and need a tune-up, then LAING can provide you with all the assistance you require.

Breathe Life Back into your Equipment and Increase Profit Margins by reducing the need to rebuy new equipment.

Save Money!

Compliance

Predict Failure

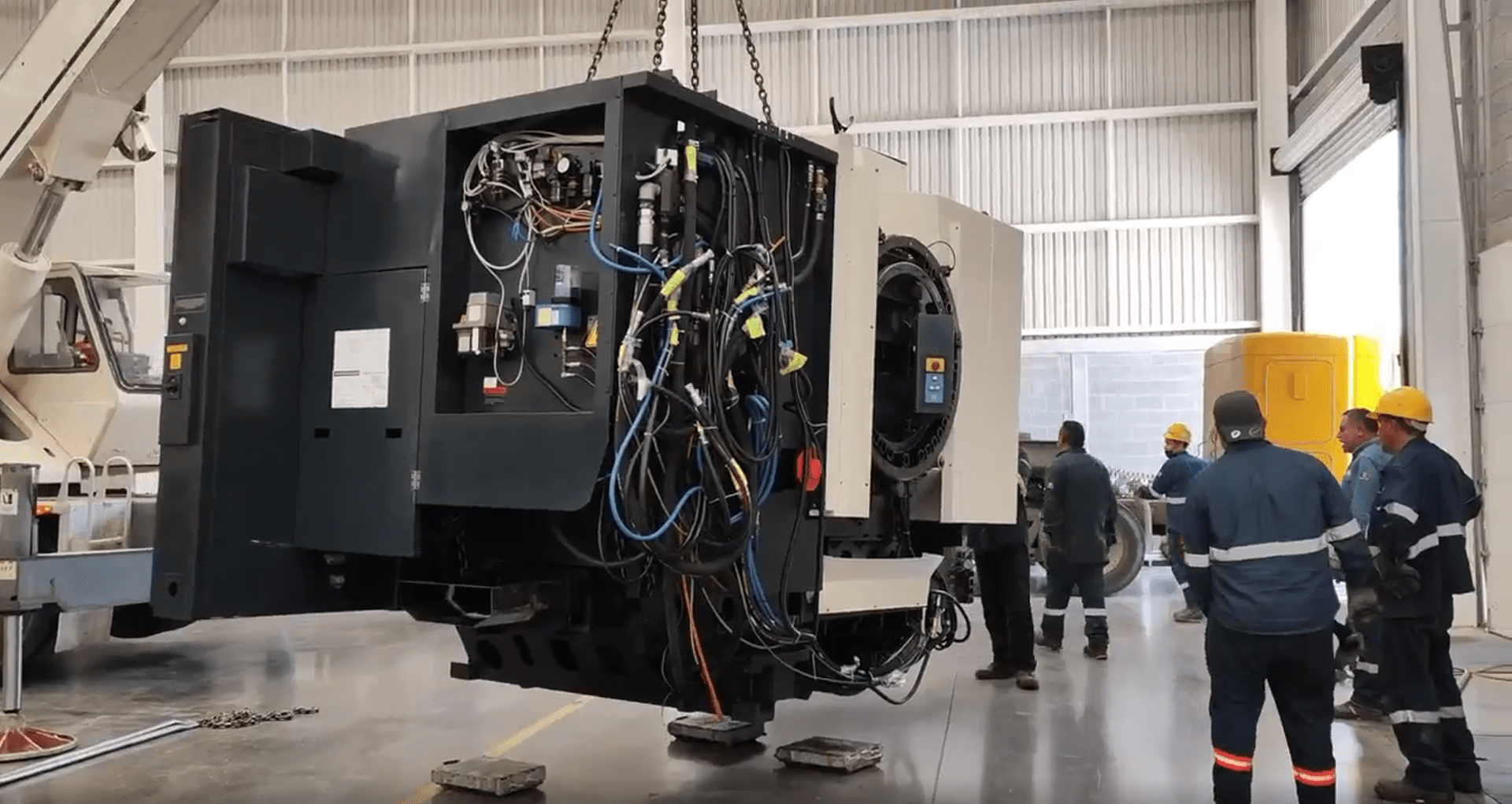

On Site Maintenance

Rigorous Testing

Services